TECHNOLOGY

Champions for innovation

30 Jul 2025

Eleven Minister for Defence Awards (MDA) were given out this year, for innovations by MINDEF and SAF personnel that led to improved efficiency and safer working conditions.

This exoskeleton suit isn’t for someone looking to dress up like Iron Man.

They were first used by Combat Service Support Command (CSSCOM) in preparing packs for the 2024 National Day Parade, where soldiers were involved in moving and lifting thousands of heavy boxes.

Visitors got a first-hand try of these suits at CSSCOM’s booth at this year’s IGNITE Innovation Symposium at the Ministry of Defence (MINDEF) on 30 Jul.

The event is held annually to honour teams and individuals within MINDEF and the Singapore Armed Forces (SAF) that have shown exceptional contributions to innovation.

Here’s a closer look at three of this year’s award winners!

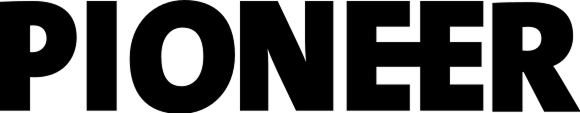

Exoskeletons in supply operations

A wearable device that is put on like a harness, the exoskeleton suit supports the user’s lower back during lifting tasks of up to 30kg.

Using sensors and electric actuators to detect the user’s movement and provide real-time assistance during lifting motions, it helps to reduce strain on the wearer’s lumbar region, thus reducing the risk of injury when lifting heavy objects.

It is among the various innovative accomplishments that clinched CSSCOM the MDA in the Non-Combat Category.

Major (MAJ) Mohamed Syafiq Bin Mohamed Shah, 32, Engineer Cluster Commander at Supply Base North, noted that feedback from users has been encouraging.

“Even though there is a need to fine-tune the selection of tasks to maximise the suit’s utility...many have reported a noticeable reduction in back strain and muscle fatigue, especially after repeated lifting tasks.”

On the future adoption of the exoskeletons for other tasks, MAJ Syafiq said: “There are ongoing efforts to assess the feasibility of scaling the exoskeleton’s use across other operations.

“Looking ahead, future iterations of the exoskeletons could benefit from a more holistic human-system integration to support the entire movement chain.”

Tracked Vehicle Autowash in Sungei Gedong Camp

The Armour Formation clinched the MDA in the Combat Category this year – a testament to their perseverance in developing a strong innovation culture that has generated over 40 ideas across two years.

One of these ideas that has been implemented on the ground is the Tracked Vehicle Autowash in Sungei Gedong Camp, which makes use of an automated, sensor-based wash system to wash tracked vehicles.

This innovative system reduces water usage, washing time, and manpower (from three crew members needed to just one!), improving the operational turnaround after training.

Speaking about how Armour’s innovation culture starts from the ground up, Chief Armour Officer Brigadier General (BG) Lim Han Yong shared that the autowash system was spearheaded by the operators in Sungei Gedong Camp.

“We believe that a culture of excellence doesn’t start at the top, it starts with every soldier. That’s why we actively empower our people at all levels to speak up, challenge norms, and drive change.

“We’ve established a clear innovation framework that enables anyone, regardless of rank, to identify issues and turn ideas into actionable solutions.”

Automated CPR Machines & Scram Bags for heli-medical evacuation operations

An MDA commendation recipient, Medical Squadron (1 MS) takes effort to cultivate the spirit of innovation in every member of the unit, and make it part and parcel of everyday operations.

For example, medics will share the challenges they face, before brainstorming together as a team to come up with feasible solutions that will help alleviate their pain points, said Commanding Officer Lieutenant Colonel (LTC) (Dr) Isaac Chay, 33.

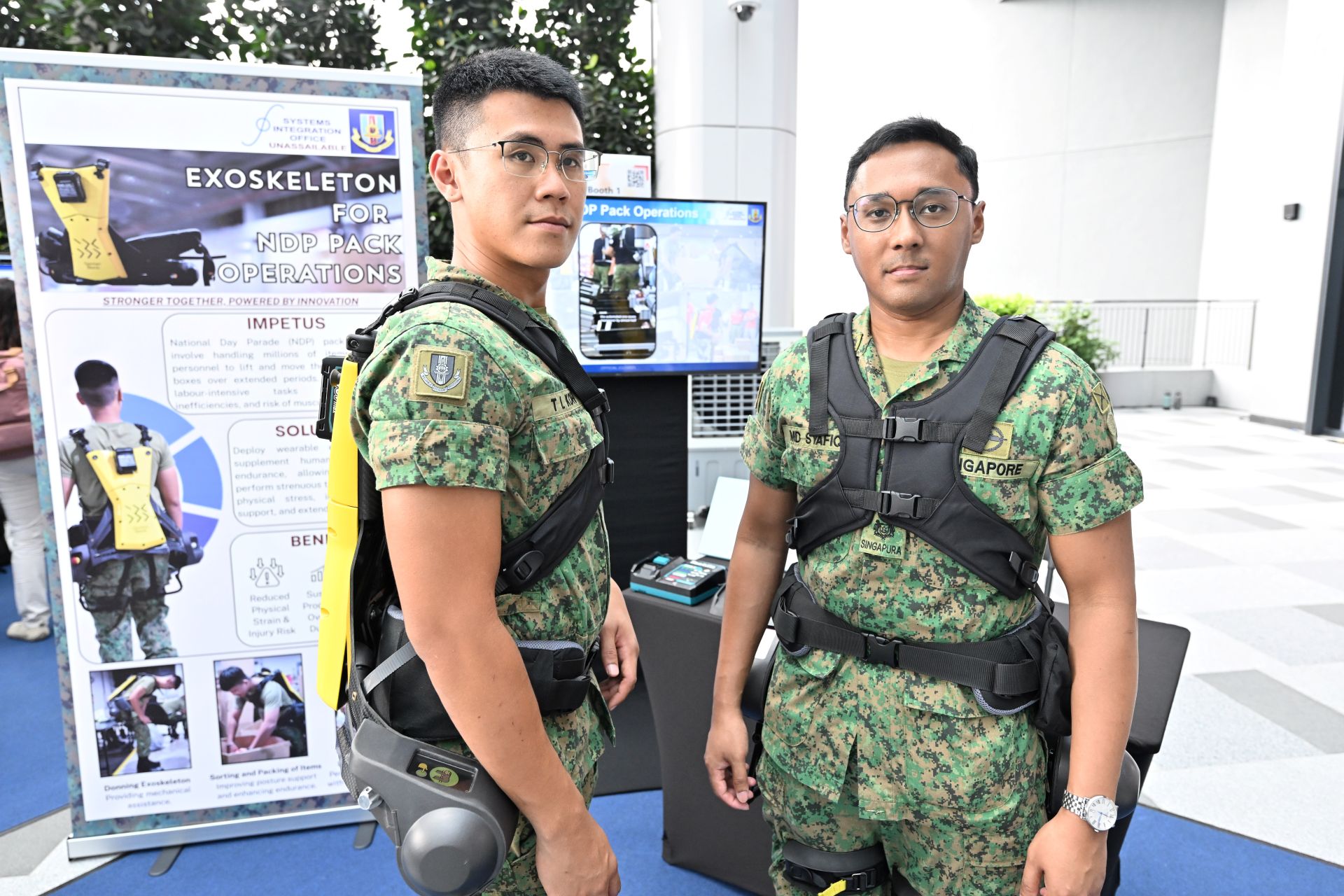

The adoption of the Automated CPR machine in heli-medical evacuation operations is one such solution.

“(The machine) really stems from a place of operational necessity to innovate and to better the way that we do things. We only have one medical officer and one medic on such missions...and so manpower is very precious,” he explained.

The usage of the Automated CPR machine frees up time for medical personnel on board the helicopter to move on to other tasks that ensure the highest quality care that the patient can receive.

SCRAM Bags, another innovation used in heli-medical evacuation operations now, came about from the input of their NSmen, which LTC (Dr) Chay noted is “a strength of their unit”.

“Instead of going to five different compartments and drawing different things, it is all now summarised within this one bag. It helps to save time as well as being efficient for the medic,” said LTC (Dr) Chay.

Commitment to innovation

Held at MINDEF on 30 Jul, this year’s award ceremony saw a total of 139 individuals, teams and units being recognised for their efforts.

Speaking at the symposium, Minister for Defence Chan Chun Sing emphasised the importance of championing the spirit of innovation in MINDEF and the SAF.

“For each and every generation of new soldiers, we must continue to imbue in them the same spirit of continuous innovation and improvement, understanding that this is fundamental to our war fighting capabilities.”

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.